Wedge wire screen, also known as Profile wire, V-wire and Tri-wire, is custom made for your specific application. The features of this type of screen makes it an attractive solution for separating solids from liquids, retaining media, filtering, sizing, dewatering, collecting and distributing.

Due to the wedge shape of the wire, wedge wire is an effective method of filtering because of the non-clogging capabilities. Wedge wire is produced in a range of sizes such as head width and profile depth with the latter having various side angles to suit a wide range of applications. Head sizes range from 1.2mm to 4.6mm with profile depths ranging from 2.5mm to 9.3mm. Please refer to the Technical Information page for an indication of open area for different wire profiles and apertures.

The wedge wire is continually wound around a set of support rods, which are either shaped or round. The wire-rod configuration can be designed to suit your specific needs. We manufacture heavy wedge wire profiles in either 304 or 316 grade stainless steel for applications involving coal or iron ore processing, or much lighter profiles, which allows for more open area for filtering fine solids from liquids.

The wedge wire is continually wound around a set of support rods, which are either shaped or round. The wire-rod configuration can be designed to suit your specific needs. We manufacture heavy wedge wire profiles in either 304 or 316 grade stainless steel for applications involving coal or iron ore processing, or much lighter profiles, which allows for more open area for filtering fine solids from liquids.

Selection of wedge wire (size and shape) is based on open area requirements, blinding considerations and wear life factors. The support rod is selected after considering the application and manufacturing capabilities. Factors in the decision may include beam strength, cost, thickness, and available support rod spacing.

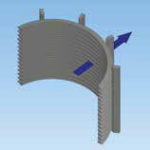

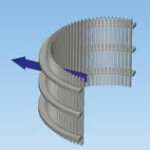

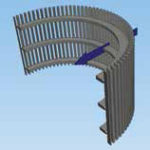

Four Possible Cylindrical Filter Configurations

| Radial Internal Opening | Radial External Opening | Axial Internal Opening | Axial External Opening |

|

|

|

|