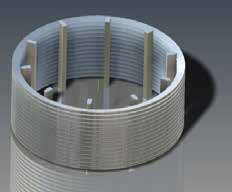

Wedge wire screens are initially manufactured as cylinders with the slots and wires running radial around the outside and support rods internal and axial. In each application every intersection of wedge wire and support rod is welded for strength. Various wire and support rod sizes can be used to produce screen designs for your particular application.

Wedge wire screens are initially manufactured as cylinders with the slots and wires running radial around the outside and support rods internal and axial. In each application every intersection of wedge wire and support rod is welded for strength. Various wire and support rod sizes can be used to produce screen designs for your particular application.

Screen cylinders can be manufactured in various standard diameters ranging from 27mm I.D. to 1000mm I.D. Cylinders with a required I.D. larger than 1000mm can be fabricated in segments. Our standard size toolings are designed to match up with standard pipe sizes to service the water bore industry.

Wedge wire screen, once manufactured, can be reverse rolled to any desired sieve radius, or flat rolled, to suit many different applications. Surround frames, or stiffener bars, can be added to suit your needs.